No two crude oils are alike, and that variability has real implications for process safety and refinery operations. Differences in composition, blending, and sourcing can significantly influence relief and flare system design requirements, tank farm behavior, and overall plant performance. As refiners adapt to shifting global supply chains, environmental regulations, and economic pressures, understanding how crude slate variability affects system performance is critical to maintaining safe, efficient, and compliant operations.

This blog highlights key findings from a recent Smith & Burgess presentation, “Scenarios in Refinery Blending & Operational Impact,” led by Co-Founders and Principal Consultants John Burgess, P.E. and Dustin Smith, P.E.

The Changing Nature of Crude Oils

Refiners today manage an increasingly diverse crude slate ranging from light, sweet U.S. shale oils to heavy, high-sulfur imports. Each crude type yields unique product distributions:

Refiners today manage an increasingly diverse crude slate ranging from light, sweet U.S. shale oils to heavy, high-sulfur imports. Each crude type yields unique product distributions:

- Light shale oils: higher gasoline and diesel fractions, minimal residue

- Traditional U.S. crudes: balanced composition, moderate reside yields

- Sour heavy crudes: high sulfur content, heavier fractions, and greater process complexity

This variability directly affects not only product output but also the hydraulic and vapor loadings that relief and flare systems must handle during both normal and upset conditions.

Why Refineries Blend Crude Oils

Blending multiple crude sources allows refiners to balance economics, availability, and performance while maintaining flexibility in operations. Common drivers include:

- Economic optimization: minimizing feedstock cost or improving margins

- Operational flexibility: adapting to seasonal demand or supply constraints

- Unit performance: maintaining throughput and product quality

- Regulatory or geopolitical factors: responding to tariffs or regional sourcing shifts

However, the flexibility that blending provides can also introduce uncertainty in relief system design, particularly when crude properties shift outside the original design basis.

How Crude Composition Affects Relief and Flare Systems and Why It Matters

At the crude unit, both composition and flowrate influence relief and flare system design. Downstream units such as the FCC, hydrocracker, and reformer are primarily affected by flowrate since the composition has already been fractionated by the atmospheric tower.

Crude blending can drive operational challenges such as:

- Floating roof instability due to lighter, more volatile materials

- Gas blowby from upstream units

- Vapor management issues in storage tanks

Even modest changes in light-end content can double the relief load on certain systems and significantly impact overall system performance.

Case Study: Hypothetical Crude Unit Scenarios

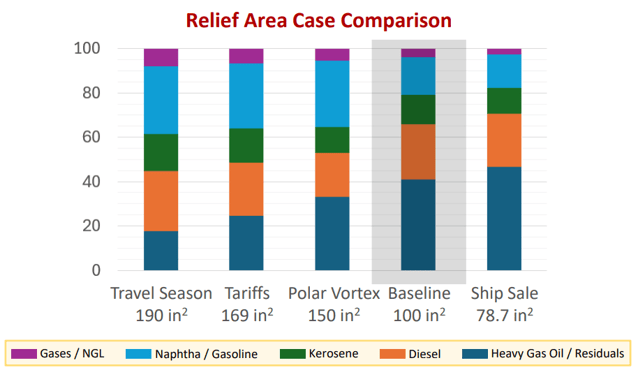

To demonstrate how crude variability directly affects process safety systems, Smith & Burgess conducted a series of simulated blending studies using the “Galveston Gushers” test refinery model. Each scenario represented a realistic shift in market or operational conditions—such as seasonal demand, tariff changes, or opportunistic crude purchases—to evaluate how different crude slates influence relief and flare loading. The following comparisons show how composition alone can significantly alter system performance, even when total charge rates remain constant.

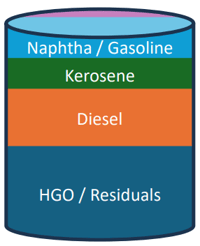

Baseline

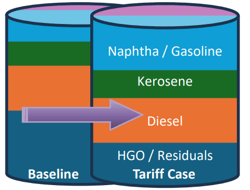

This blend represents a balanced processing strategy based on typical regional availability. It serves as the foundation for evaluating relief and flare system impacts in subsequent

scenarios.

Composition: 50% Venezuelan, 25% West African, 25% Gulf Coast

Relief and Flare Loading: 100,000 lb/hr (Mass Flow)

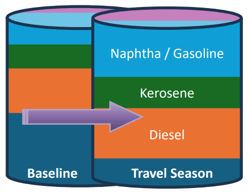

Travel Season

A seasonal blend prioritizing gasoline, kerosene, and diesel to meet travel demand.

Composition: 50% West African, 25% West Texas Intermediate, 25% Eagle Ford

Change in Loading: +54% mass flow

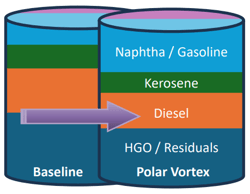

Polar Vortex

Blend designed for extreme winter conditions, favoring heating fuels.

Composition: 50% Canadian, 50% Eagle Ford

Change in Loading: +25% mass flow

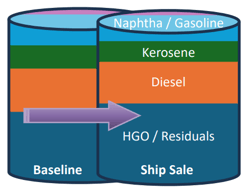

Ship Sale

Opportunistic purchase of discounted heavy marine crude.

Composition: 75% Venezuelan, 20% West African, 5% Gulf Coast

Change in Loading: –13% mass flow

Tariff

Reflects sourcing shifts due to tariffs, increasing reliance on domestic crude oils.

Composition: 50% Gulf Coast, 20% West Texas Intermediate, 30% Eagle Ford

Change in Loading: +40% mass flow

These results underscore how seemingly small shifts in crude sourcing can create substantial differences in relief and flare system demands. In total, required relief area varied from 80% to 190% of the baseline—demonstrating that feedstock selection alone can more than double relief capacity requirements for the same throughput.

Key Takeaways

- Crude composition matters. Even small changes in feedstock can significantly impact relief and flare system performance.

- Design assumptions must evolve. Relief systems sized for a single crude basis may be undersized or oversized under new operating conditions.

- Operational coordination is critical. Process safety, operations, and planning teams must communicate crude sourcing decisions and validate relief basis assumptions regularly.

- Effective relief system management ensures compliance, reliability, and safe performance across all blending and operating scenarios.

Understanding how crude slate variability influences relief and flare system design allows facilities to make informed operational and investment decisions. By anticipating how crude changes affect relief loads and vapor management, refiners can improve reliability, reduce unplanned downtime, and maintain compliance with process safety standards.

About Smith & Burgess

Since 2007, Smith & Burgess has supported global refiners and chemical manufacturers with process safety expertise, pressure relief system design, and facility siting studies. With more than 3,000 projects successfully completed and approximately $300 million in client cost savings, Smith & Burgess serves as a trusted partner in maintaining safe, reliable, and compliant operations.

Read the full presentation here: https://bit.ly/3VOzuft