Did you know, relief devices that protect process pipe may be set to open above the piping design pressure?

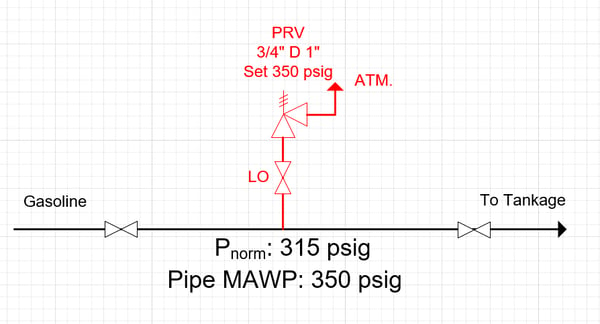

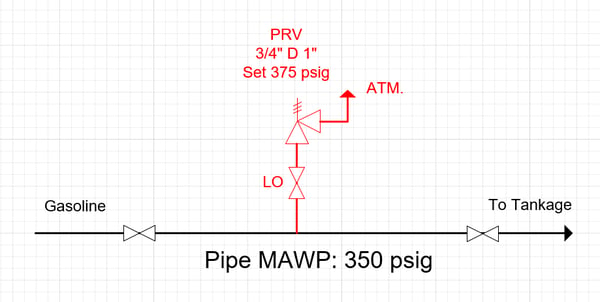

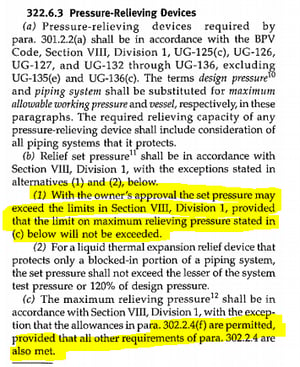

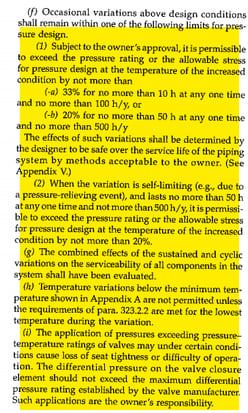

Per ASME B31.3-2016, Sections 322.6.3. (see Figure 1) and 302.2.4 (f) (see Figure 2), a thermal relief valve may be set up to 120% of the design pressure of the protected system with the owner’s approval, as long as, the allowable accumulation criteria in 302.2.4.(f) are met. Set pressures lower than 120% of the design pressure may be required depending on the allowable accumulation pressures in 302.2.4 (f).

The following is a summary of the ASME B31.3 rules:

- PSV set pressure should be accordance with Section VIII, Division 1 with exception stated below.

- With the owner’s approval the set pressure may exceed the limit in Section VIII, Division 1, as long as 302.2.4 (f) are also met.

- 302.2.4 (f) states that the design conditions shall remain within one of the following:

- Owner’s approval that it is permissible to exceed the pressure rating or the allowable stress for pressure design at the temperature of the increased conditions but not more than 33% for no more than 10 h at any one time and no more than 100h/y, or 20% for no more than 50 h at any one time and no more than 500h/y.

- When the variation is self-limiting (e.g., due to a pressure relieving event), and lasts no more than 50h at any one time and not more than 500h/y, it is permissible to exceed the pressure rating or the allowable stress for pressure design at the temperature of the increased condition by not more than 20%.

- The effects of the sustained and cyclic variations on the serviceability of all components in the system shall have been evaluated.

|

Figure 1: ASME B31.3 Section 322.6.3 |

Figure 2: ASME B31.3 Section 302.2.4 |

|

|

|

Operating Pressure within 90% of the PSV Set Pressure...

You may experience leakage through a conventional/balance bellows relief valve protecting process pipe. The protected system is probably operating within 90% of the set pressure. Per API STD 520 Sixth Edition, Part II, Section 4.4, this can cause leakage at the seat of PRV, premature opening, or premature fatigue failure of certain valve parts or piping.

Knowing that B31.3 allows set pressures higher than design pressure, you may be able to suggest increasing the PSV set pressure to mitigate the leakage.