Did you know, a relief device in liquid service does not always mean that the device is liquid-certified?

Liquid-certified devices are mechanically designed and sized by an engineer to relieve liquid. Per UG-125 of ASME Section VIII, "Vessels that are to operate completely filled with liquid shall be equipped with pressure relief devices designed for liquid service, unless otherwise protected against overpressure."

Pressure relief valves fall under three general categories based on definitions from Appendix I of ASME PTC 25. These definitions are listed below:

- Safety Valve: An automatic pressure relieving device actuated by the static pressure upstream of the valve and characterized by full-opening pop action. It is used for gas or vapor service.

- Relief Valve: An automatic pressure relieving device actuated by the static pressure upstream of the valve which opens further with the increase in pressure over the opening pressure. It is used primarily for liquid service.

- Safety Relief Valve: An automatic pressure-actuated relieving device suitable for use either as a safety valve or relief valve, depending on application.

In other words, a relief valve is categorized by gradual lift that is usually proportional to the increase in upstream pressure while safety valves are fast acting, rapid lifting devices. Safety relief valves fall in a hybrid category. For these reasons, relief valves and safety relief valves are utilized for liquid service.

Per API 520 Part I, "The ASME Code requires that capacity certification be obtained for PRVs designed for liquid service. The procedure for obtaining capacity certification includes testing to determine the rated coefficient of discharge for liquid PRVs at 10% overpressure." Prior to this capacity certification requirement, liquid service devices were generally sized based on an effective coefficient of 0.62 and 25% overpressure due to their slow opening characteristic.

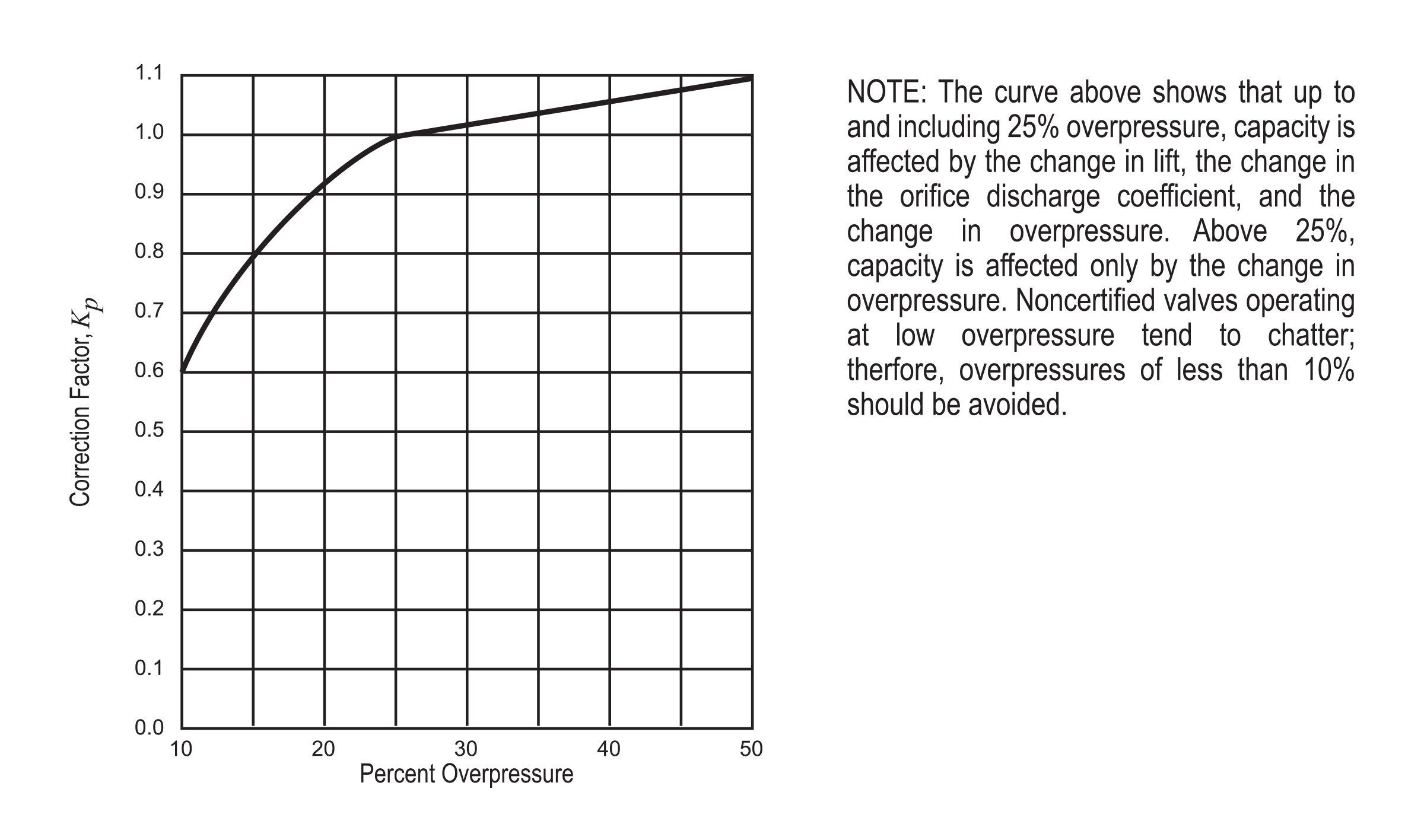

Refer to the attached figure from API 520 that illustrates the Capacity Correction Factors Due to Overpressure for Noncertified PRVs in Liquid Service. The capacity correction factor does not reach 1.0 until 25% overpressure. At 10% overpressure, the capacity correction factor (Kp) is only at 0.6. For this reason, liquid relief device sizing calculations when analyzed at 10% overpressure must be run at a derated capacity as the non-liquid-certified valve will only be partially open.

If project guidelines call for the use of ASME orifice size and manufacturer's Kd, and the valve is certified for liquid relief, make sure to utilize the values provided in either the manufacturer's catalog or the National Board PRD Certifications book (NB-18). Care should be taken as some manufacturer series may indicate liquid certification through obscure designations, and superficially appear similar to non-certified series numbers. The NB-18 Certifications book can provide indication or confirmation that the valve model has been certified for liquid flow. If the valve is not certified for liquid flow, consult your technical lead for an approved path forward. One potential option is to implement the API orifice and Kd and use the liquid-non-certified sizing equation for these situations.